Written by Pennie Burnham, Nycote Laboratories Corporation

Microbiologically influenced corrosion (MIC) refers to biocorrosion, which occurs when microorganisms break down materials. MIC is recognized worldwide as an important corrosion category, and can lead to significant asset losses and dangerous conditions across all industries.

Billions of dollars have been dedicated to understanding how microorganisms affect different industrial materials, and it is estimated that about 20% of all corrosion failures are due to microbially induced corrosion. (Flemming, 1996; Beech and Gaylarde, 1999).

What is the cost of corrosion today?

In 2016, the global cost of corrosion was estimated to be $2.5 trillion annually. More than $500 billion of this cost may be due to MIC. Microbiologically influenced corrosion is acknowledged to be the direct cause of catastrophic corrosion failures. Despite extensive research and numerous publications, many questions remain about MIC.

More about Nycote Technology: Paint & Coating Best Practices for Aerospace Applications

Microorganisms’ Role on Earth

Somewhere around 2.4 billion years ago, Cyanobacteria (blue-green algae) began to form. The small organisms are partly responsible for the oxygen we breathe today. We may perceive microorganisms as our enemies. However, microorganisms perform a vital ecological role.

The sole responsibility of microorganisms is to grow, spread, break down matter, and effectively keep the earth clean. When you see material breakdown, you are witnessing nature's cleaning process taking place.

Since we like to live in houses, drive cars, and fly in planes, material breakdown is not something we tolerate. We are in a constant battle to delay this natural process for as long as possible. Humans have been trying to do just that for the past 2000 years, maybe more.

Roman philosopher Pliny, AD 23-79, wrote about Ferrum corrumpitur, or spoiled iron. Since Pliny lacked the ability to investigate the problem scientifically, he determined that iron is both the best and the worst of man's servants.

More about Nycote Technology: Antimicrobial Solutions in Aerospace: What's it really mean?

What Helps Microbes Grow

In most cases, microbes need three things to grow and spread successfully:

1. Moisture

Fungi are moist living organisms that do not photosynthesize, meaning they multiply by spreading or by releasing their spores. They grow rapidly in damp, dark places. These living organisms are very well adapted to absorbing nutrients from soil and substrates.

2. Food Source

Living organisms need food to survive. Fungi receive their nutrients from the material 'they're growing on. Most fungi are decomposers and break down the complex carbon compounds that are part of living matter.

3. Oxygen

While some fungi and bacteria can survive without oxygen, the types that cause corrosion are obligate aerobes, and they require oxygen to grow. These types of microorganisms secrete corrosive fluids that degrade materials, even those that do not provide nutrients.

Two Reasons Aerospace & Defense Industries are Investing in MIC Prevention

The appearance of U.S. Department of Defense (DoD) visual information does not imply or constitute DoD endorsement.

1. To Reduce Risks and Costs Associated with MIC

Aerospace & Defense part and system failures caused by corrosion are always industry's greatest concern. Until recently, Chrome and Heavy Metals were the industry's primary weapons to protect structures from corrosion-causing microbes and harsh environments.

While chrome continues to be used on aircraft structures today, these products are to be entirely banned by 2024. Abundant research and development dollars are being filtered to companies and organizations to find suitable replacements before hard chrome is completely banned.

Replacing hard chrome is challenging due to the immense amount of aerospace specifications requiring it. Replacing chrome has significant considerations, such as, environmental operating conditions, functionality and relationship to other parts and mechanisms.

2. To Understand MIC Electrochemistry and the Degradation Process they Cause

Investment in new corrosion prevention strategies and materials is critical because of the increasing pressure to eliminate chrome and heavy-metals. New strategies and advanced materials may also extend asset lifespan and reduce weight and fuel consumption.

Safety is a key concern for investment dedicated to studying microorganism electrochemistry and new materials resistant to their processes. The Aerospace and Defense industry must ensure safety, both directly and indirectly, to humans, assets, and our environment.

How We Prevent MIC Now and What Methods We Can Expect in the Future

Industries are facing unique materials and chemical challenges when it comes to MIC as microorganisms can be difficult to locate and eliminate.

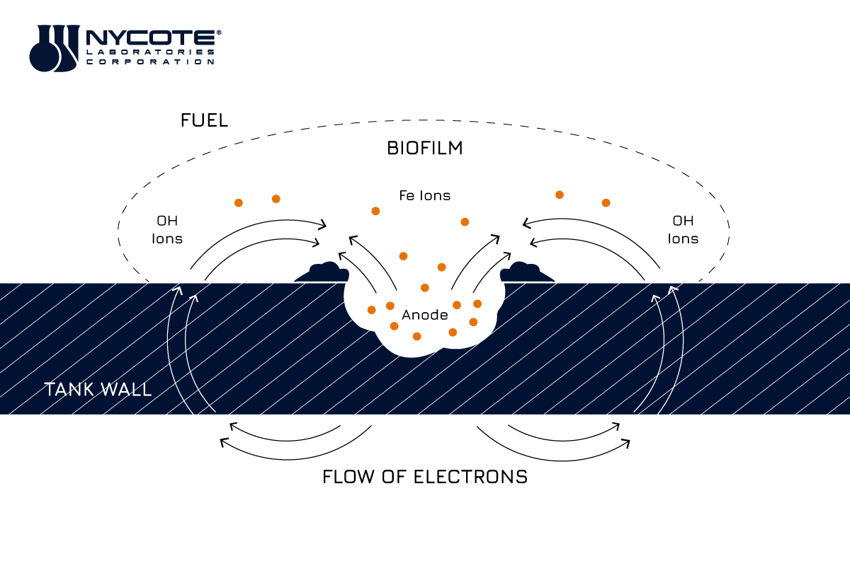

MIC, including bacteria, fungi, archaea, and microalgae, can directly or indirectly influence corrosion, depending on the microorganisms’ material and electrolyte-specific reactions.

Corrosion can develop quickly once a protective barrier is disturbed. This is why preventing the breach of the protective layer is so important. To reduce the potential threat posed by MIC, we consider many factors.

Material Selection

MIC prevention should start with ideal material selection. Engineering teams will likely consider materials that have the best chance of resisting their environment for an appropriate amount of time. For example, the skin of the aircraft is made from aluminum alloy 6061 due to its corrosion-resistant properties and good formability aspects.

Materials for integral fuel tanks are typically made from 3003 or 5052 aluminum alloy or stainless steel. Integral tanks are cavities within the airframe structure that are sealed to form fuel tanks. They are less prone to leakage, which explains the willingness to pay the weight penalty.

Integral fuel tanks are fabricated like the rest of the plane. As permanent fixtures, they are not easy to inspect, maintain, and repair. They are also prone to microbial attacks due to the nature of the materials that must be used; this is why thousands of hours are spent annually to inspect and maintain fuel tanks and systems. While MIC can be found on many aircraft parts and systems, fuel tanks are highly susceptible.

Fuel tank and fuel system manufacturers are investing in research and development activities to introduce innovative materials to the market. These innovations are directed toward optimizing the strength of the aircraft fuel tank and reducing the weight of the aircraft.

The ultimate aim of fuel tank innovations is to enhance overall efficiency. Markets and Markets estimated the aircraft fuel tank market would be $869 million in 2019, or at a CAGR of 1.6% during the forecast period. It remains unclear how much of that is earmarked for MIC research and technology.

Locating Microbial Corrosion in Fuel Systems

Image courtesy of Seal Aviation

MIC, or biocorrosion, is caused by activity of microorganisms on parts or in systems. As the organisms grow, they become slimy biofilm mats that can cause considerable damage.

1. Inspection, Maintenance, and Removal

Preventing MIC starts with excellent inspection and maintenance practices for all types of corrosion. General corrosion, pitting, stress-corrosion cracking, environmental embrittlement, corrosion fatigue and exfoliation must be addressed continuously because degradation can occur very quickly, in days or even hours. To effectively remove the microbial black sludge from fuel tanks, all affected parts and systems must be cleaned, treated and resealed.

2. Fuel Tank and Containment Systems

Fuel tank and containment systems are perfect environments for bacteria and fungus found in the fuel tank's lowest points or trapped in areas of the tank collecting water. Where there is water, microbes grow. Over time, filamentous fungi (black sludge photographed above) can break off and can cause equipment like gauges to malfunction, lines to become clogged, and metal to corrode.

3. Future MIC Prevention

Next-generation aircraft design has been strongly influenced by the need to reduce the weight of the aircraft, which conserves fuel consumption and reduces the carbon footprint. A typical jet produced today has as little as 20% pure aluminum. Materials considered acceptable for non-structural aesthetic purposes are now made from lightweight carbon fiber reinforced polymers (CFRP's) and honeycomb materials. While the goal is to reduce weight and increase efficiency, many of these materials may be less conducive to microbial proliferation.

How Nycote Coatings Protect Against the Destructive Effects of MIC

Nylon is naturally microbial resistant. When formulated into a precise coating, it is an extremely effective barrier between your aircraft parts and the environment. Nycote 7-11 has been applied to fuel tanks and containment system parts for decades to prevent MIC. The unique formulation is a clear thin nylon polymer-epoxy coating that microorganisms cannot penetrate or grow on. It is now being used on aircraft interiors to reduce the risks of microbial proliferation on surfaces.

Nycote protective coatings were introduced to the aerospace and defense industries in the 1960s. They have been a proven, trusted solution for all types of corrosion prevention ever since. Nycote 7-11 was created to protect metal and electronics from the harsh effects of Skydrol (hydraulic fluid) and jet fuel like JP 4, 5, 6, 8, & 10.

The use cases have evolved into new products and an expansive library of applications. Mission-critical applications for electrical systems, fuel containment systems, avionics, drain-masts, and sensors, are just some of 7-'11's capabilities.

Now a new generation of products like Nycote 99 Ecoshield, and NyGone are being tested by aerospace OEMs with excellent results. We are also in R&D on a virucidal coating formulation that will be a safe and effective alternative to many other products on the market. Nycote remains the only clear, lightweight, liquid nylon polymer-epoxy system that is simple to use and highly effective.

More about Nycote Technology: Advantages of Nycote's Self-Leveling, Nylon Epoxy Polymer

3 Reasons to Have Nycote Coatings on Your Company's Qualified Product List

- Nycote Laboratories incorporates unique coating technology formulations proven over decades to solve corrosion issues, protect electrical systems, and prevent environmental wear.

- Clear nylon-polymer-epoxy extends the asset lifespan and can reduce maintenance costs.

- Nycote has an excellent 60-year reputation for collaborating with and learning from our customers. We have formulated our products based on our aerospace customers' needs and can meet their unique specifications.

More about Nycote Technology: Download Safety Data Sheets for Nycote Products

Contact us at sales@nycote.com to speak with a technical specialist or visit our website at https://www.nycote.com/ for more information.